Recent groundbreaking work from the research team led by Professor Wang Gang at the College of Materials Science and Engineering has been published in several top-tier international journals, including National Science Review, Advanced Materials, and Advanced Functional Materials. These consecutive achievements demonstrate the team's comprehensive capabilities spanning ‘spinnability, patternability, and integrability,’ laying a solid foundation for the scalable application of fiber-based intelligent systems.

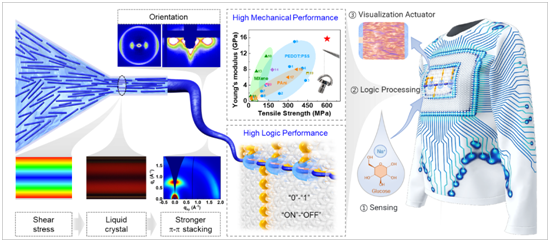

At the level of spinnable materials and formation, the team proposed a novel ‘shear-enhanced liquid crystal spinning’ strategy. By applying controlled shear to induce an anisotropic liquid crystal phase in the microfluidic spinning zone and locking in the molecular orientation and crystalline order during solidification, they produced integrated semiconductor fibers (exemplified by BBL) with high alignment, high crystallinity, and high electrochemical performance. The resulting fibers exhibit a Young's modulus of approximately 15.3 GPa and a tensile strength of about 600 MPa, while maintaining stability under extreme temperatures, strong UV exposure, and harsh acidic/alkaline/organic solvent environments. OECTs constructed from these fibers show significantly higher mobility and transconductance in the axial direction than in the radial direction and maintain stable operation for over 10,000 gate pulse cycles. Furthermore, the team successfully demonstrated logical discrimination of sweat ions and glucose on a textile platform and, in combination with electrochromic fibers, realized a visual health monitoring system featuring ‘sensing–decision–display’ functionality. These results have been published in National Science Review.

Figure 1. Shear-Enhanced Liquid Crystal Spinning for Polymer Semiconductor Fiber Fabrication

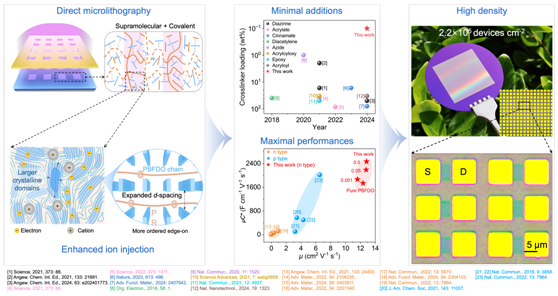

At the level of patternable precision manufacturing, the research team addressed the mass production requirements for high-density flexible/bioelectronics by proposing a novel ‘direct micro-photolithography (DML) via supramolecular synergy’ paradigm. By introducing trace amounts (<0.1 wt%) of a polyrotaxane crosslinker, a dual network combining hydrogen bonding and photo-induced covalent bonding was constructed within an organic ion-electron mixed conductor (PBFDO), enabling coordinated regulation of the polymer microstructure and ionic channels. While maintaining excellent ion/electron coupling, the process achieved a pattern resolution of 600 nm and wafer-scale OECT integration with a density of 2.2×10⁵ devices•cm⁻², significantly enhancing device mobility and transconductance. These findings have been published in Advanced Materials.

Figure 2. Wafer-scale integration of organic semiconductor transistors enabled by direct micro-photolithography for synergistic opto-electro-ionic performance

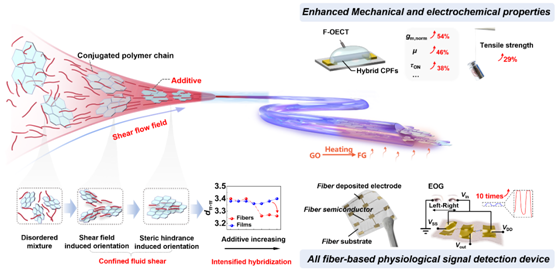

At the integrable device and system level, the research team proposed a ‘shear-enhanced hybridization’ technique. By introducing functionalized graphene during the wet spinning process, dual optimization of molecular orientation and π-π stacking is achieved, resulting in the construction of highly oriented and conjugated hybrid fibers. This strategy yields synergistic enhancement in mechanical strength, modulus, and intrinsic charge transport, leading to a more than 50% improvement in the geometry-normalized transconductance of fabricated fiber-based OECTs, along with faster response times and superior stability. Leveraging the matched performance of n-type and p-type fiber devices, the team further developed a fully fiber-based p-n complementary inverter, achieving low-voltage amplification of electrooculographic (EOG) signals with a gain of approximately 90 V/V, thereby completing the closed-loop validation from material to device to system. This work has been published in Advanced Functional Materials.

Figure 3. High-performance conjugated polymer fibers and subsequent fiber-based organic electrochemical transistors fabricated through shear-enhanced hybridization

These three achievements are closely interconnected in the research pathway, forming a comprehensive technological chain encompassing material development, precision manufacturing, and system integration. At the material level, ‘spinnability and synergistic performance enhancement’ are realized through liquid crystal shear and hybrid enhancement. At the manufacturing level, supramolecular DML enables submicron-scale patterning and wafer-level high-density integration. At the system level, an integrated ‘sensing–computing–display’ validation is accomplished on textile platforms, demonstrating potential applications in health monitoring, neural interfaces, wearable computing, and related fields.

The research was led by Donghua University in collaboration with international teams including Linköping University in Sweden and Sichuan University, with funding from the National Natural Science Foundation of China and the National Key R&D Program. Moving forward, the team will systematically advance multi-material coordination, end-to-end mass manufacturing, and standardized reliability assessment, aiming to achieve greater breakthroughs in the industrialization of ‘semiconductor fiber + intelligent systems.’