Rainy season clothing hairy, moldy walls trouble people for many years, recently, Associate Professor Yang Zili’s team from the College of Environment of DongHua University made a breakthrough in development of environmentally friendly “anti-mold vaccine”. Through three innovative technologies, the anti-mold is as simple and safe as ‘vaccination’. The research was supported by the National Natural Science Foundation of China, and the results were presented at the 11th China (Shanghai) International Technology Import and Export Fair.

Traditional mold inhibitor is like a ‘chemical weapon’, relying on toxicity to kill mold, but harmful to the human environment. The team pioneered the “metabolic disruption” technique, which is like feeding molds ‘sugar substitutes’ -- so that they happily consume ‘fake nutrients’ but are unable to grow, and ultimately ‘starve to death’ in the reproduction phase. The research to non-toxic small molecules instead of toxic chemicals, targeted destruction of mold genetic material, compared to the traditional mold inhibitor dosage reduced by 80%, and colorless and odorless, sprayed at the immediate formation of a protective film. The laboratory data shows that even in extreme environments with humidity of 95% ~ 99%, the effect of mold is still close to 100%. “This is like a room inoculated with ‘mold vaccine’,” Yang Zili, project leader said, "spray coating can be maintained throughout the rainy season protection effect, food storage, home environment and even basements can be applied." The research results of safe and harmless, efficient and long-lasting, environmentally friendly and other features directly hit the pain point of mold, through three major technological innovations to achieve efficient anti-mold.

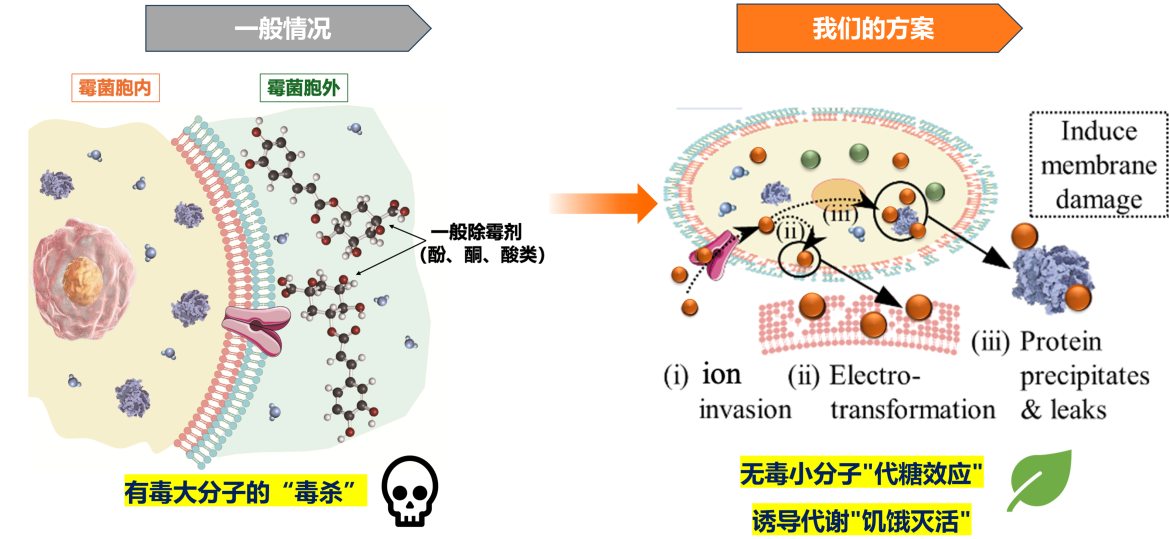

Breakthrough 1:from ‘poisoning’ to ‘starvation inactivation’——Let the mold die out in the metabolism, no matter how humid or wet it is.

Traditional mold removal technology is usually used with strong oxidative or toxic phenols, acids, and even ketones and other chemicals, these toxic macromolecules usually destroy the mold cell wall membrane structure of the mold ‘poisonous’, but at the same time there will be a toxic component of the spillover or by-products and other hazards, is not suitable for use in the human environment. The team discovered a new material exchange channel in the metabolic process of mold cells, and cleverly adopted the logic of ‘sugar substitute’ similar to that in ‘sugar-free’ beverages, and put forward a new method of mold inactivation: through a kind of non-toxic, tasteless, but very preferred by mold in the metabolic process and small molecules, which can be used to kill mold. In the peak period of mold reproduction constantly intake of the nutrient-free ‘sugar-free substances’, so as to avoid the proliferation of the first generation of mold life cycle, induced metabolism ‘starvation Inactivation’. Due to the first generation of mold ingesting too much ‘sugar-free food’ and ‘starvation inactivation’, even if the environment is very humid and can provide sufficient moisture to the mold, the mold eventually died because of insufficient nutrient intake. This technology realizes the cross-border upgrade from ‘poisoning’ to ‘starvation inactivation’, even if the environment is humid and wet, there is no fear of mold growth.

(from ‘poisoning’ to ‘starvation inactivation’—Let the mold die out in the metabolism)

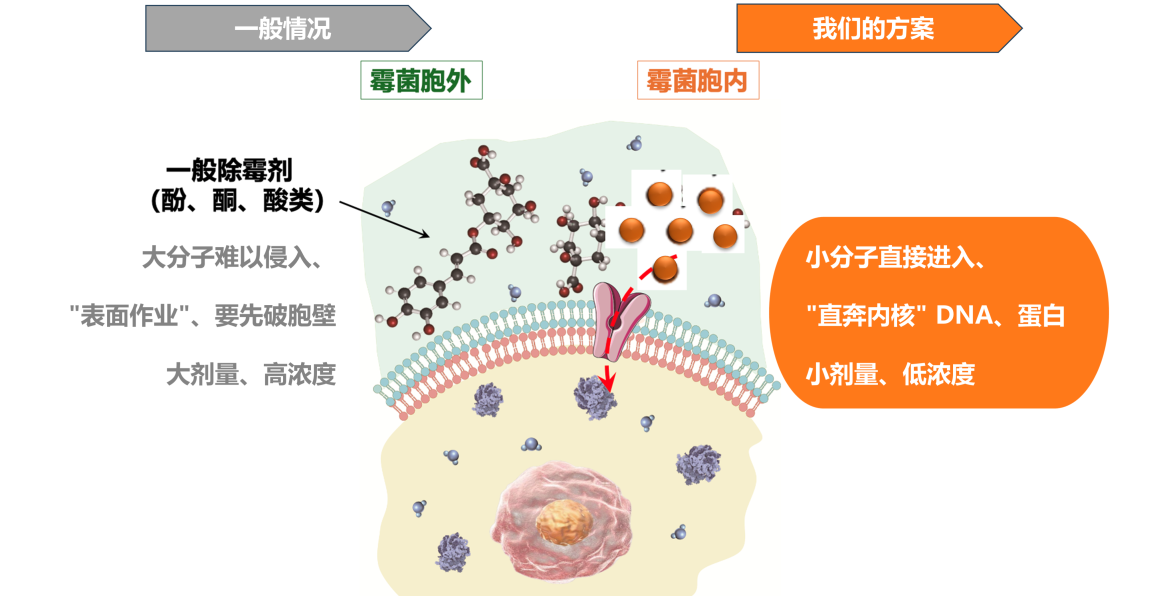

Breakthrough 2:Improved invasion of mold spores -- straight to the mold kernel, low concentration in small quantities.

Mycobacteria are self-regulating microorganisms that produce a stress response when confronted with macromolecules from existing inactivation techniques and resist invasion by these harmful macromolecules. For this reason, the molecules of existing inactivation technology is difficult to invade the internal mold spores, usually need to work on the surface of the cell wall membrane, the first destruction of the mold cell membrane before invading the intracellular protein and genetic material. This makes the current mold products need large doses, high concentration to ensure a certain inactivation efficiency while research team innovation to change the way to invade the mold spores, through the development of the ‘sugar substitute components’ small molecules, camouflage through the mold cells and the environment of the material exchange channel, and ‘go straight to the core’, invade the intracellular and attached to intracellular proteins and genetic material, change its structure, so that the mold in the proliferation process can not recognize the required proteins and genetic material. Thanks to this, the technology requires only a small dose, low concentration can be achieved with high efficiency inhibition of the bacteria, and at the same time to avoid the impact on the environment and the infliction of matrix.

(straight to the mold kernel, low concentration in small quantities)

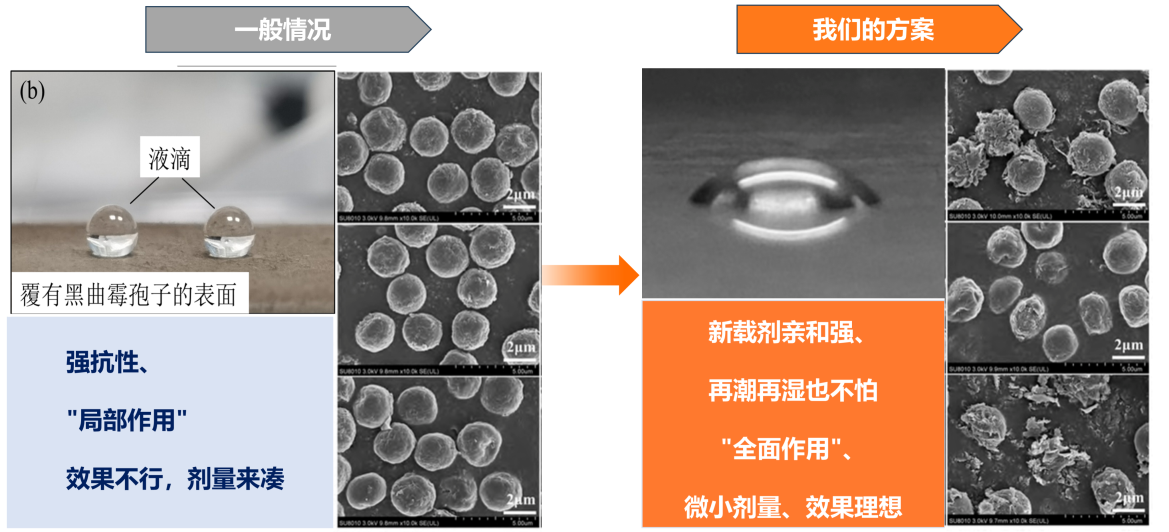

Breakthrough 3: the use of new safe carrier -- inhibition efficiency increased to nearly 100%

Mold both love and hate water, mold like moist environment to absorb water to proliferate, but its own and show a strong hydrophobicity, thus showing strong resistance to traditional mold removal technology, so that it is ‘local role’ and can not eradicate mold, resulting in repeated mold problems. The research team targeted the development of a new type of safe carrier, build mold cells and ‘anti-mold vaccine’ connecting bridge and strengthen its affinity, to achieve the ‘full effect’. Under extreme humid environment, the ‘anti-mold vaccine’ can also effectively act on the mold cells to maximize the effect of ‘starvation and inactivation’. Laboratory tests, in 28-30 ℃, 95-99% humidity mold incubator, sprayed with anti-mold vaccine samples inhibition efficiency is always maintained at nearly 100%.

(New safe carrier helps to maintain the efficiency of “anti-mold vaccine” at nearly 100% for a long period of time)

Research-related results published in the international journal ‘Building and Environment’ , the series of technology has completed the laboratory verification, and the team is working with enterprises to promote industrialization. This technology is expected to completely solve the mold and mildew in the south of China, Southeast Asia and other regions of the trouble.