The team of academician Zhu Meifang and researcher Cheng Yanhua from the State Key Laboratory of Advanced Fiber Materials of the University and the College of Materials Science and Engineering has made a breakthrough in the continuous preparation of flexible heat-insulating aerogel fibers. Traditional aerogel is difficult to withstand the bending/tensile stress and washing process in practical applications due to defects such as intrinsic brittleness, poor processability and insufficient mechanical strength, and is prone to structural collapse and loss of heat-insulating function. Although existing aerogel fiber preparation techniques (e.g., freeze-spinning and wet-spinning) can realize fiber preparation, they still face three challenges: (i) insufficient mechanical strength; (ii) difficulties in continuous production; and (iii) the introduction of functional fillers significantly deteriorates the spinning liquid spinnability.

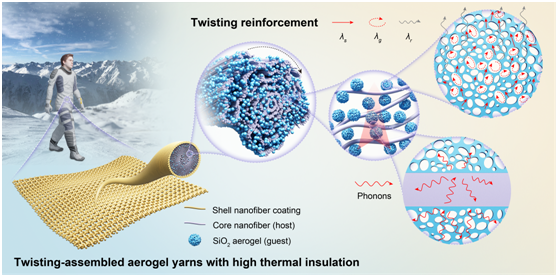

To address the above technical bottlenecks, the research team proposed the Roll-to-RollTwisted Assembly strategy. Using a two-dimensional nanofiber membrane as the structural skeleton, the technology successfully composites high-content (78 vol%) commercial mesoporous SiO2 aerogel particles uniformly into the yarn matrix through a one-step spraying-twisting integrated process. Compared with the conventional process, this method eliminates complex post-treatment steps such as solvent exchange and supercritical drying; realizes the continuous and efficient production of aerogel yarn; and the product exhibits excellent thermal insulation performance (thermal conductivity of 32.3 mW-m-1-K-1, better than cashmere and cotton). By optimizing the twisting angle to 35°, an Archimedean helix structure is created, resulting in a yarn with significantly enhanced mechanical properties: a tensile strength of 16.3 MPa, a load carrying capacity of 3.3 x 104 times the dead weight, and a significant increase in structural stability. In addition, NF-TAY shows excellent durability: it maintains good mechanical and thermal insulation properties after extreme temperatures (-196~100 °C), repeated folding/compression and 100 washes. Through the functionalized modification of the outer nanofibers, NF-TAY is also hydrophobic (contact angle of 146°), dyeable, and Joule-heated, enabling it to meet different application scenarios and individual needs. The related results were published in Advanced Materials under the title of ‘Roll-to-RollTwisted Aerogel Yarns with Reinforced Structure and Low Thermal Conductivity’.

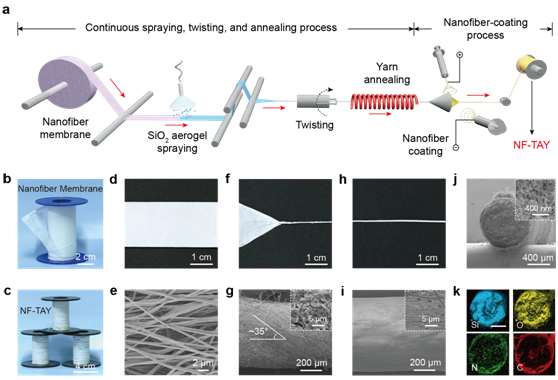

Fig. 1 Preparation process of aerogel yarn and its micro-morphology characterization

Fig. 1 systematically demonstrates the roll-to-roll twisting assembly process and yarn morphology. The flow schematic clearly presents the three-step core process: (1) spraying SiO2 aerogel/hexane dispersion on the surface of PAN nanofiber membrane; (2) twisting to form Archimedean helical-structured yarn; (3) encapsulation of the outer layer of PAN nanofibers.

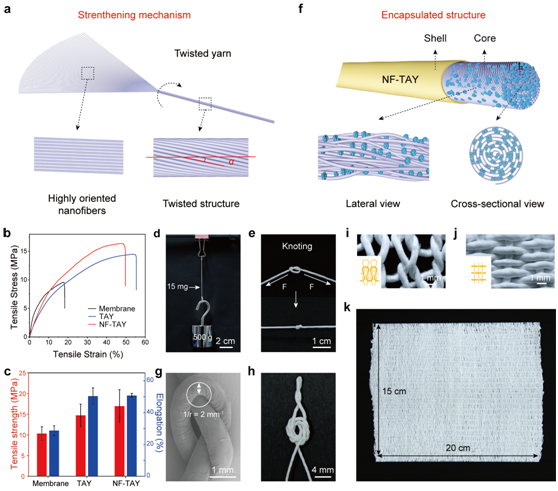

Fig. 2 Mechanical properties and knittability of aerogel yarns

Fig. 2 demonstrates the mechanical enhancement mechanism and application potential of the yarns, with a dual enhancement mechanism embodied in two aspects: the contribution of the highly oriented nanofibers, and the optimization of the structure through the twisting angle in order to enhance the inter-fiber friction.

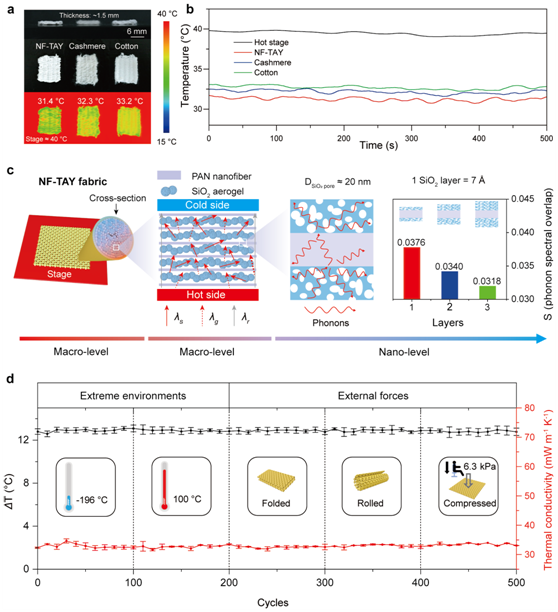

Fig. 3 Thermal protection performance and service stability of aerogel yarn

Fig. 3 analyzes the thermal insulation performance and multi-scale heat transfer mechanism of aerogel yarn, which is mainly reflected in three aspects: 1) aerogel pore size is smaller than the mean free range of air molecules, which inhibits the gas-phase heat transfer through the Knudsen effect; 2) nanofibers enhance the light scattering, thus reducing the radiative heat transfer; and 3) the high porosity and weak nanofibers/inter-aerogel van der Waals forces enhance phonon scattering and reduce solid-phase heat transfer. In addition, the aerogel yarn maintains stable thermal insulation performance after high and low temperature cycling, folding and compression.

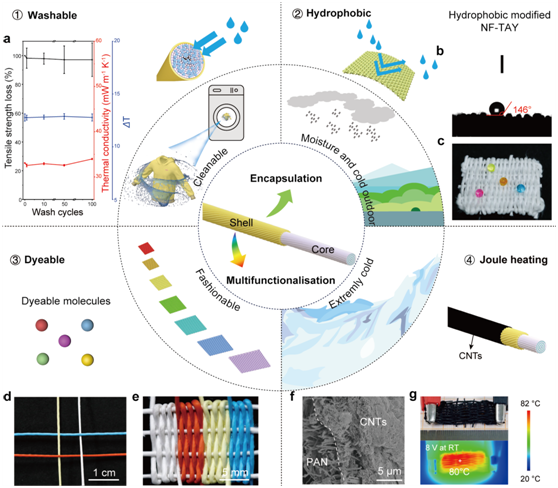

Fig. 4 Multifunctional aerogel yarn application

Fig. 4 demonstrates the functional extension and practical scenario adaptability of aerogel yarn. The research team verified its excellent washing stability: after 100 washes, the strength loss of the aerogel yarn was <3%, and the thermal insulation performance remained basically unchanged. In addition, by functionalizing the outer nanofibers, the yarn achieves hydrophobicity (contact angle of 146°), dyeability, and Joule heating (up to 25 °C at 8.2 V) to meet different application scenarios and individual requirements.

Link to original article:https://advanced.onlinelibrary.wiley.com/doi/10.1002/adma.202507289