Ceramics is an important and indispensable material in human society, but its inherent brittleness and non-deformability have severely restricted its application in cutting-edge technologies. For example, the thermal protection of high-speed aircraft involves the mechanical environment of severe impact and high-frequency vibration, while flexible wearable devices need to withstand repeated twisting or bending stress; these application scenarios require ceramic components to integrate high strength, large bending strain, and even plastic deformation, but this is unimaginable for traditional ceramic materials. In this context, the development and exploitation of one-dimensional ceramic nanofibers provide an important direction to solve the brittleness problem of ceramic materials. However, the above mechanical integration has not been realized on ceramic nanofibers so far due to the challenges of multiscale defects caused by conventional preparation methods and the difficulty of precisely regulating the microstructure.

Recently, Prof. Ding Bin and Prof. Liu Yitao of Donghua University synthesized for the first time a long chain of inorganic molecules with linear structure, and spun them to create ceramic nanofibers with flexible/elastic properties, which realized the overall enhancement of mechanical properties of fibers. The research results were published in Nature Communications under the title ‘Integration of high strength, flexibility, and room-temperature plasticity in ceramic nanofibers’.

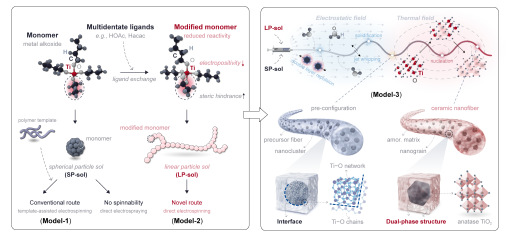

(Schematic representation of the creation of biphasic structured ceramic nanofibers based on long chains of linear inorganic molecules)

In order to solve the above problems, the research team designed a new route of ligand modification and restricted hydrolysis-polycondensation reaction of metal-alcohol salt monomers, and prepared long chains of inorganic molecules with linear structures. Taking titanium system as an example, the synthesized linear inorganic molecules can be directly used in electrostatic spinning (‘self-template’ method), effectively breaking through the bottleneck of the traditional preparation route, which relies heavily on polymer templates. On this basis, the research team further proposed a molding method of crystalline/amorphous biphasic structure ceramic nanofibers based on interfacial nucleation regulation, and the resulting biphasic structure titanium oxide (TiO2) nanofibers have a dense and defect-free morphology and a diffuse structure with a uniform distribution of nanocrystals, which makes the ceramic monofibers have both high strength, excellent flexibility and room temperature plasticity.

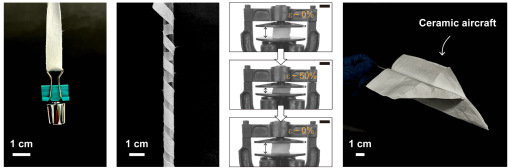

Taking TiO2, a typical brittle ceramic material, as an example, the uniformly embedded nanocrystals in the amorphous matrix play a key role in structural stabilization, while the amorphous matrix acts as a soft boundary to fully dissipate external stresses. In addition, the optimized dual-phase configuration effectively alleviates the local stress concentration across scales and fully activates multiple deformation mechanisms including bond switching, grain rotation, and delayed activation of shear bands, resulting in simultaneous enhancement of the tensile strength, strain limit, and bending flexibility of TiO2 nanofibers, which can reach a tensile strength of 1.06 GPa, a tensile strain limit of 8.44%, and the bending flexibility is excellent (curvature radius < 0.47 μm). The research team further assembled the ceramic nanofibers into two-dimensional fiber membranes and three-dimensional fiber aerogels, which demonstrated excellent flexibility and elasticity characteristics respectively, and proved their great potential and value in extreme application scenarios or complex stress environments.

(Demonstration of flexible/elastic properties of ceramic nanofiber materials)

The related research results were published in Nature Communications, with corresponding authors Prof. Bin Ding and Prof. Yitao Liu, and first author Siyu Qiang, a PhD student at Donghua University. The above work was supported by the National Natural Science Foundation of China and the Shanghai Natural Science Foundation.

link to full artical :https://doi.org/10.1038/s41467-025-58240-4