In recent years, frequent oil spills have posed a threat to marine ecosystems and human health. Traditional oil spill treatment methods, such as chemical dispersants, in situ combustion and mechanical recovery, suffer from secondary pollution and low efficiency. Therefore, the development of efficient, environmentally friendly and recyclable oil spill adsorbent materials has become an important current research direction.

Recently, Prof. LI Faxue's team and Prof. Zhang Ruiyun's team from the College of Textiles, Donghua University were inspired by the microstructure of locust leaf pimples and cooperated to construct a carbonized electrostatic flocking fabrics (HMDS-SiO2 modification of the carbonized electrostatic flocking fabrics, HC-CEFF). This fabric utilizes the synergistic effect of photothermal-electrical heat to achieve rapid cleanup of heavy oil. The above research results are presented as ‘Bioinspired Design of Textile-based Absorbers: Photothermal and Electrothermal Synergistic Conversion for Efficient Heavy Oil Cleanup’ and was published in Advanced Fiber Materials.

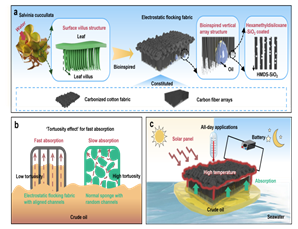

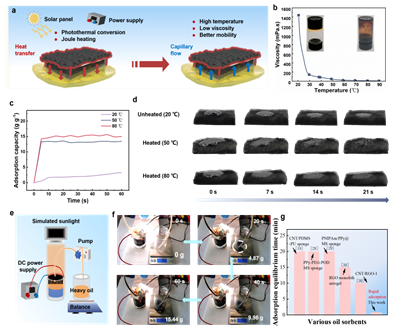

The core of this design strategy consists of two parts: first, the vertically aligned high-density carbon fibers have rough hydrophobic surfaces and low tortuosity, which are conducive to reducing oil diffusion resistance and facilitating the rapid adsorption of heavy oil on the basis of strong capillary forces. Secondly, the carbonized cotton fabric and vertically aligned carbon fibers can achieve excellent photothermal conversion and Joule thermal performance due to their excellent light absorption properties and good electrical conductivity (Figure 1).

Fig. 1. Schematic diagram of solar-heated and joule-heated HC-CEFF absorber for heavy oil purification

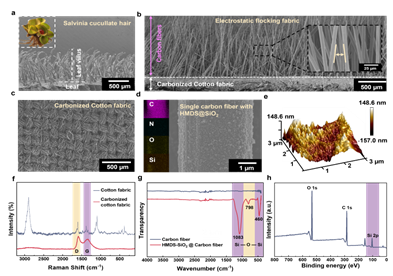

By the action of an electrostatic field, the carbon fibers are vertically aligned on the carbonized cotton fabric basecloth (Figure 2). Numerous open and well-aligned pores are formed between the carbonized cotton fabric and the carbon fibers. the low orientation of the HC-CEFF absorber enhances the capillary effect, reduces flow resistance, and improves fast oil absorption.

Fig. 2. Morphological characterization and chemical structure characterization of HC-CEFF absorber

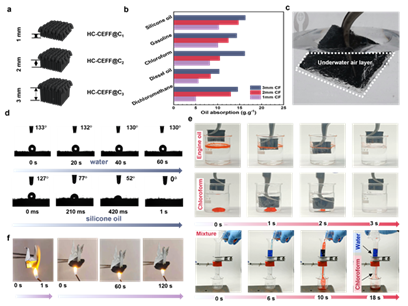

HC-CEFF absorbers have good hydrophobicity and lipophilicity. Among them, HC-CEFF@C3 (carbon fiber flocking length of 3 mm), had the highest absorption of all organic solvents (14.59 g g-1 for dichloromethane, 10.36 g g-1 for diesel fuel, 16.17 g g-1 for chloroform, 14.36 g g-1 for gasoline, and 16.32 g g-1 for silicone oil).

Figure 3. Demonstration of the wettability and oil absorption of HC-CEFF

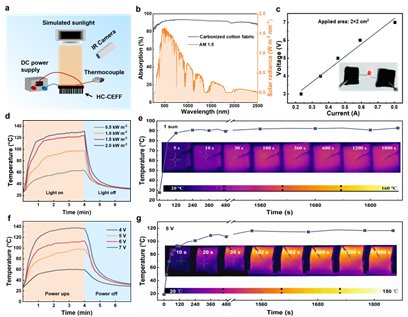

The photothermal and electrothermal properties of HC-CEFF were evaluated by temperature changes under different light intensities and voltages.HC-CEFF@C3 has a broadband solar absorption of 95%. When the solar intensity is 1 kW m-2, HC-CEFF reaches 91.0 °C in 120 s. The solar intensity of HC-CEFF@C3 is 1 kW m-2, and the solar intensity of HC-CEFF@C3 is 1 kW m-2. At a voltage of 5 V, the temperature of HC-CEFF@C3 gradually increased and remained stable, with the highest value of 98.0 °C, respectively (Fig. 4).

Fig. 4. Plot of photothermal and electrothermal performance data of HC-CEFF

Finally, the heavy oil adsorption performance of the HC-CEFF absorber was explored. After 1 min at 1 kW m-2 of solar illumination and 5 V, 15.44 g of heavy oil could be collected (collection rate of 2,647 kg h-1 m-2) (Fig. 5).

Fig. 5. Recovery of heavy oil by HC-CEFF absorber

In summary, inspired by the downy structure of acacia leaf ping, heat-assisted textile-based HC-CEFF absorbers prepared by scalable electrostatic flocking technology can be used for fast and efficient absorption of heavy oil.The high absorbance and resistivity of the HC-CEFF absorbers bring about excellent photothermal and electro-thermal effects, which can effectively reduce the viscosity of heavy oil. Bio-inspired solar-heated and Joule-heated textile absorbers with open-arrangement structures have a large potential for efficient and practical heavy oil recovery.

Link to the full article: https://doi.org/10.1007/s42765-024-00423-7