China Daily: Weaving glory

By He Qi | China Daily

The Yan'an Road campus of Donghua University in Shanghai's Changning district.

[Photo provided to China Daily]

Donghua University has contributed significantly to the development of China's textile industry over the past 70 years, He Qi reports in Shanghai.

Last month's safe return of the three crew members of the Shenzhou XII mission was an achievement not just for China's space program but also for Donghua University in Shanghai.

In 2015, the university won the bid to design some shoes and clothing for the astronauts.

Zheng Rong, a professor at the university and chief designer of the shoes that took more than two years to develop, says that due to weight requirements, shoes for the mission were created using thermoplastic and blended knitted materials so that they would be much lighter than conventional ones.

Since Donghua is well-versed in fiber development, textile processes and the design, manufacturing and functional evaluation of clothing, we were able to provide the necessary items for the mission, says Li Jun, dean of the college of fashion and design who led the team that designed clothing for the astronauts.

This isn't the first time the university has designed such clothing. In addition to the formal military uniform of the People's Liberation Army, spacesuits worn by Jing Haipeng and Chen Dong, the astronauts on the Shenzhou XI space mission in 2016, were also created by the university.

Although functionality is key in this context, the design team went the extra mile to consider aesthetics. For example, skirts and scarves were specially designed for female astronauts, says Zhou Honglei, a professor in the team.

Li says the university has completed the clothing for astronauts assigned to the Shenzhou XIII space flight, which is slated to launch this month.

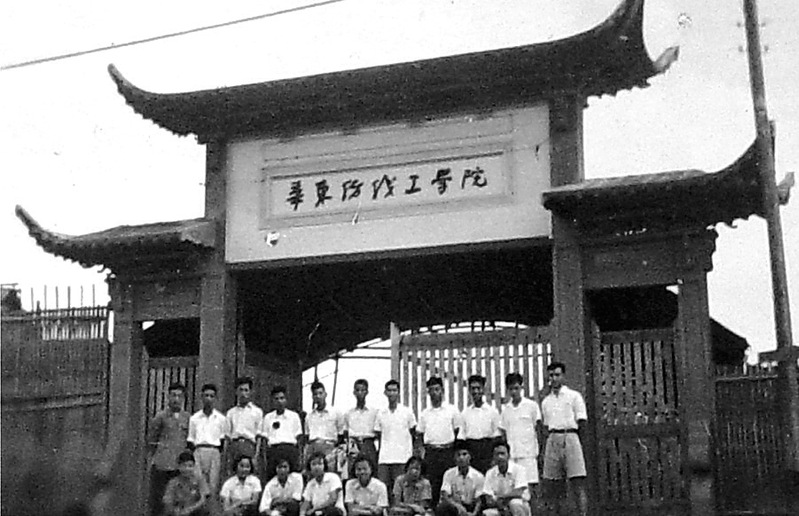

A group of teachers and students pose in front of the newly founded East China Textile Institute of Technology in the 1950s.

[Photo provided to China Daily]

Pioneering force

Donghua University has a record of contributing to the development of various sectors in China, including the aerospace industry, over the last 70 years.

Founded in 1951, following the merger of the textile departments of several universities, including Shanghai Jiao Tong University, Donghua was first called East China Textile Institute of Technology. It was renamed China Textile University in 1985 and Donghua University in 1999.

After the founding of New China in 1949, the country needed to spur development in various areas, including the production of both synthetic and natural fibers to meet the practical needs of hundreds of millions of people.

Qian Baojun, the former president of the university, realized that the top priority was to develop the chemical-fiber industry, and this needed to begin with cultivating more talent.

As such, Qian and Fang Bairong, a chemical-fiber expert, wrote to the Ministry of Textile Industry and proposed the establishment of China's first chemical-fiber major in the university. The proposal was approved in 1951.

The school received and trained the first batch of students learning to make chemical fibers in 1954. After only four years, the first batch of professional technicians was able to contribute to the industry and alleviate the shortage of talent in China at that time, says Zhang Qianli, curator of the Donghua University archives.

In 1960, the university was turned into a national key university with a 600-member faculty that helped to form a higher-education system for textiles. Training textile workers to support the industry was the university's key objective during that period.

Pan Ding (center) leads a team of researchers on carbon fiber technology.

[Photo provided to China Daily]

Led by Wei Dachang from its department of textile machinery, the university started to explore high-speed spinning equipment and polyester-filament spinning technology in the 1970s. A team of 80 experts from different departments then spent eight years researching such areas, resulting in the debut of high-speed spinning in China in 1985.

The university won the special prize for scientific and technological achievement given by the Shanghai Textile Bureau that same year. It was also included in the national plan for tackling key problems in science and technology during the Sixth Five-Year Plan (1981-85) and named the winner of the second prize in the National Science and Technology Progress Awards in 1987.

The team mastered the process of spinning 6,000 meters of polyester filaments a minute in 1991 and won the gold award at the first Shanghai Science and Technology Expo.

Because of these achievements, the high-speed spinning engineering group went on to undertake nine projects in Shanghai and Jiangsu, Zhejiang and Guangdong provinces, starting in 1991. By 1993, the annual production of polyester filament in China reached 24,000 metric tons, while the output value of the material stood at 336 million yuan ($52 million).

The projects have not only produced remarkable economic benefits, but also brought huge social benefits. Besides directly supporting many enterprises, they have played a key role in promoting the development of China's chemical-fiber industry, Zhang says.

The university has received nearly 50 national awards related to science and technology since 1985.

The university wins the bid to design shoes and clothing for astronauts in the country's space missions.[Photo provided to China Daily]

Spreading wings

The university's innovation prowess has also been gradually extended to the aerospace industry.

Pan Ding from the college of materials helped the country become one of three nations to master the technology required to produce aerospace-grade high-purity viscose-based carbon fiber.

Han Wenjue, who's also from the university, played a pivotal role in designing the passivated glass for the flight used in the Shenzhou V mission, which carried Yang Liwei, China's first astronaut, to space in 2003.

Another researcher, Zhang Weiyuan, and colleagues used a thermal manikin to collect data related to metabolic energy, heat transfer and skin temperatures of astronauts under simulated space conditions.

The university's Protective Clothing Research Center conducts research on protective clothing for activities related to high altitudes, antiterrorism, disaster prevention and emergency rescue.

Today, the university's fashion-design students are frequently seen at fashion weeks.

The university has held a series of high-level international academic conferences, including the 83rd Textile World Conference and the Textile and Fashion Education World Conference, both of which have forged closer ties with more than 160 universities and enterprises across the world.

The university has also provided textile-related teaching resources in the Xinjiang Uygur autonomous region and launched the world's first Confucius Institute with a focus on textiles at Moi University in Kenya.

Former vice-chairman of the Chinese People's Political Consultative Conference National Committee, Chen Jinhua, once commented that, as the cradle of talent in the textile industry, Donghua University has helped China to become a major textile producer in the world.

The university now has three campuses in Shanghai's Songjiang and Changning districts. It's no longer just a specialist college but an institution that teaches engineering, art, science, management and other disciplines.

Design students leave mark on fashion week

By He Qi | China Daily

Donghua University alumni have become a common sight at the annual Shanghai Fashion Week.

Among the latest under the spotlight are Zeng Yue and Fu Fanding, the founders of fashion brand Momonary that released its 2022 spring/summer collection last week at the TRI art place in the city.

Momonary's presence in the industry has grown quickly since its founding in 2019, and this eventually drew the attention of Labelhood, a designer-incubation platform, which helped the brand make its debut at the fashion week last year.

Zeng, who earned her master's degree from Central Saint Martins in London, was the winner of Donghua's 2018 Cutting-Edge Designers competition. The award presented her with the opportunity to display her designs at the London Graduate Fashion Week that same year.

Donghua University has cultivated many students like Zeng and Fu every year since 2015.

According to Wang Zhaohui, vice-dean of the College of Fashion and Design at Donghua University, the institution set up the Donghua Cutting-Edge Designers program in 2015 to cultivate talented students with a global vision.

Ten senior students from our college are selected as part of the program every academic year, and each student needs to design six sets of clothes that are released at the Donghua Cutting-Edge Designers event at Shanghai Fashion Week, Wang says. The top designer selected then participates in the international design competition at London Graduate Fashion Week that year.

According to Wang, the first cooperation between the university and Shanghai Fashion Week was in 2016. Twenty-four designers got to showcase their works at the event.

To date, 72 Donghua University students or alumni have participated in Shanghai Fashion Week. Among them, 11 have been named Cutting-Edge Designers, two have won international fashion awards and nine have established independent designer brands.

According to Wang, 30 percent of those selected from the program have received postgraduate offers from top international fashion institutions, such as Central Saint Martins, the Royal College of Art and the University of the Arts London.

We have been actively building a platform for students to connect with society, says Wang, adding that designers can transform the textile, clothing and fashion industries.

Let the young talent wear the halo of Donghua's Cutting-Edge Designers to better and faster fit in the domestic and international fashion markets. This is the value of the program.

Alumni become trailblazers, stitching together the future

By Xing Yi | China Daily

Zhu Wenbin (left), a doctoral student of Donghua University, undertakes fabric research with his team.

[Photo provided to China Daily]

Donghua University in Shanghai has supported the entrepreneurship of its students and alumni as one of the best schools to study textiles in China. Ma Feifei, who did a master's program in textile engineering from the university, is one such beneficiary.

In 2016, Ma founded Shanghai Sturdy Armor New Material Technology Co, which was a continuation of his graduate project in which he invented a type of polymer compound that was inspired by the structure of pangolin scales. Ma named the material Saintfabric.

According to Ma, the soft and light fabric can resist knife cuts and stabs of up to 1,100 newtons.

The teachers at Donghua University were very helpful when I was creating the prototype and doing lab testing, Ma says.

Besides learning textile engineering, he also got tips on how to run his own business through workshops organized by the university's innovation and entrepreneurship center.

The material he created has since been granted several government patents in China. It has passed quality assessments conducted by the public security authority. Bodyguards and bank-security teams were among his first customers, says Ma.

After six years of marketing and upgrading his product, Ma says his company has grown to become one of the leaders in this market segment. He says the company also supplies stab-proof vests and shirts, and other tactical clothing to clients abroad. About 60 percent of his sales are from overseas, he adds.

Shanghai is an international metropolis, and coming here and studying in Donghua has definitely broadened my horizons as I got the chance to listen to lectures by top experts and participated in many first-class expos in the industry, says Ma.

Zhu Wenbin, an entrepreneur and doctoral student at the university, also benefited from the university's research resources when he was developing Mintblue, a material that changes color when exposed to contaminants.

The idea behind this fabric came to Zhu when he was pursuing a joint master's degree offered by Donghua University and Philadelphia University from 2011 to 2014, he says.

After graduating from the program, Zhu worked for a year before founding his company, Nianfu Technology, to commercialize the research for the new material.

When the fabric is tainted by grease, sweat or bacterial metabolites, among other undesirable substances, the color of special strips changes from blue to pink. When the pollutants are washed away, the color changes to blue again.

The technology has been applied to various products, such as towels and underwear. It has also won many awards, including the 2017 China Top 10 Innovative Textile Products prize.

Zhu was named in the 2017 30 under 30 Forbes China list.

I am now researching the visualization of sanitary safety, says Zhu, who returned to the university to do his doctoral studies in 2019. With the experiences I have had in the industry, I want to help other students turn their research into products.

Source:China Dail